New 3D printer can create complex biological tissues

A UCLA Samueli-led team has developed a specially adapted 3D printer to build therapeutic biomaterials from multiple materials. The advance could be a step toward on-demand printing of complex artificial tissues for use in transplants and other surgeries.

"Tissues are wonderfully complex structures, so to engineer artificial versions of them that function properly, we have to recreate their complexity," said Ali Khademhosseini, who led the study and is UCLA's Levi James Knight, Jr., Professor of Engineering at the UCLA Samueli School of Engineering. "Our new approach offers a way to build complex biocompatible structures made from different materials."

The study was published in Advanced Materials.

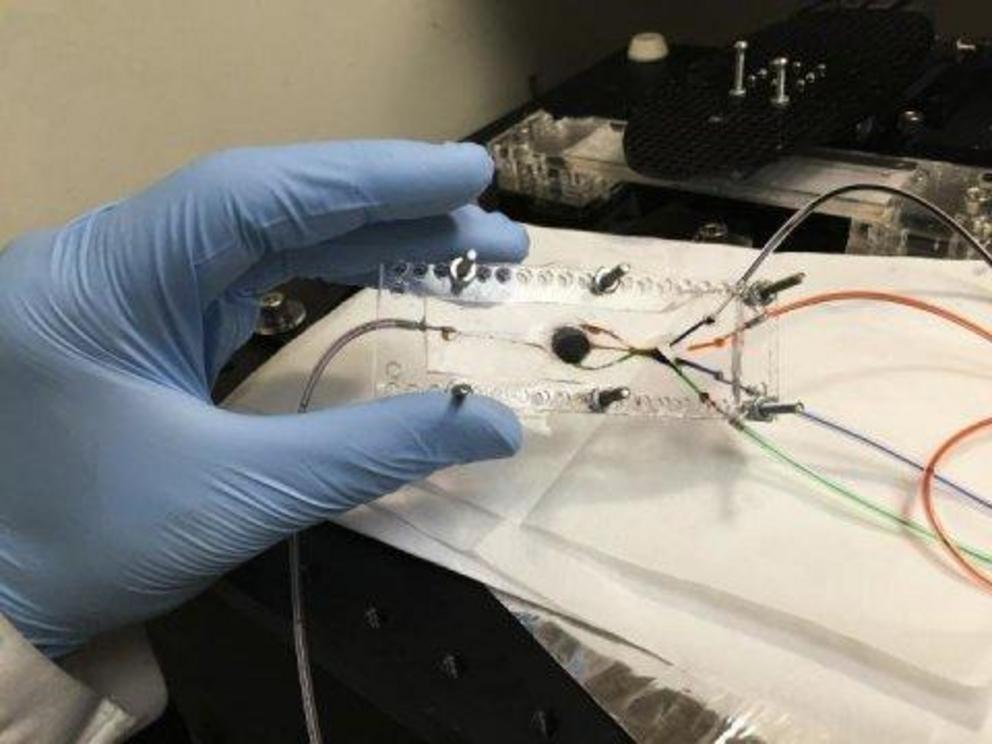

The technique uses a light-based process called stereolithography, and it takes advantage of a customized 3D printer designed by Khademhosseini that has two key components. The first is a custom-built microfluidic chip -- a small, flat platform similar in size to a computer chip -- with multiple inlets that each "prints" a different material. The other component is a digital micromirror, an array of more than a million tiny mirrors that each moves independently.

The researchers used different types of hydrogels -- materials that, after passing through the printer, form scaffolds for tissue to grow into. The micromirrors direct light onto the printing surface, and the illuminated areas indicate the outline of the 3D object that's being printed. The light also triggers molecular bonds to form in the materials, which causes the gels to firm into solid material. As the 3D object is printed, the mirror array changes the light pattern to indicate the shape of each new layer.

The process is the first to use multiple materials for automated stereolithographic bioprinting -- an advance over conventional stereolithographic bioprinting, which only uses one type of material. While the demonstration device used four types of bio-inks, the study's authors write that the process could accommodate as many inks as needed.

The researchers first used the process to make simple shapes, such as pyramids. Then, they made complex 3D structures that mimicked parts of muscle tissue and muscle-skeleton connective tissues. They also printed shapes mimicking tumors with networks of blood vessels, which could be used as biological models to study cancers. They tested the printed structures by implanting them in rats. The structures were not rejected.

Journal Reference:

- Amir K. Miri, Daniel Nieto, Luis Iglesias, Hossein Goodarzi Hosseinabadi, Sushila Maharjan, Guillermo U. Ruiz-Esparza, Parastoo Khoshakhlagh, Amir Manbachi, Mehmet Remzi Dokmeci, Shaochen Chen, Su Ryon Shin, Yu Shrike Zhang, Ali Khademhosseini. Microfluidics-Enabled Multimaterial Maskless Stereolithographic Bioprinting. Advanced Materials, 2018; 1800242 DOI: 10.1002/adma.201800242

UCLA Samueli School of Engineering. "New 3D printer can create complex biological tissues: Device could help advance regenerative medicine." ScienceDaily. ScienceDaily, 21 May 2018. <www.sciencedaily.com/releases/2018/05/180521092744.htm>.