3D printed eagle eye from University of Stuttgart gives micro-machines the power to see

A miniature camera made by a team of optical researchers and physicists in Germany uses four 3D printed lenses to mimic the way our eyes, and those of predators, capture light.

Occupying a space of only 300 μm × 300 μm (the approximate length x width of 6 human hairs) the lenses can be added to the likes of miniature drones and robots used to navigate areas or record images of the surroundings.

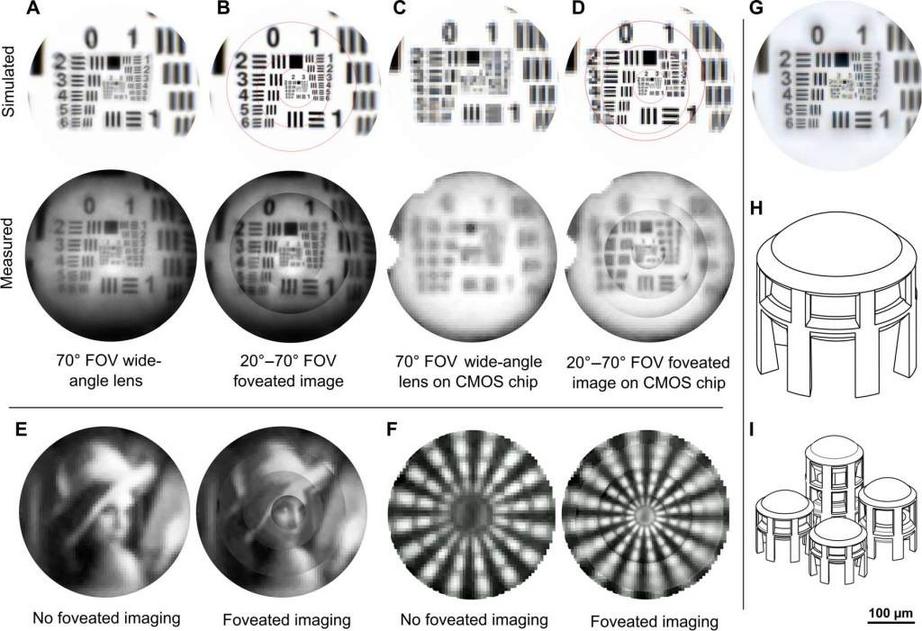

Simulated and actual images taken by the eagle eyed camera from Stuttgart University. H, I show the design of the micro lenses. Figure via Simon Thiele, Kathrin Arzenbacher, Timo Gissibl, Harald Giessen & Alois M. Herkommer

Four ‘eyes’ for one image

One of the main obstacles to 3D printing a lens is in the optical quality created by layering material. In an entirely 3D printed camera, designer Amos Dudley had to perform various methods of post-processing to the lens to rid it of layers visible to the human eye.

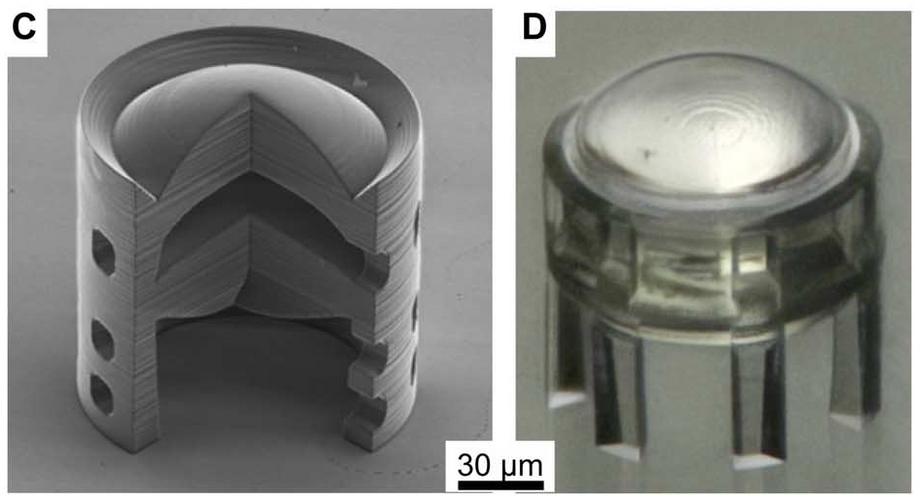

The University of Stuttgart’s eagle eye still has microscopic layers in its formation, but the design of each lens makes them almost irrelevant: light travels through the top down, instead of from the side where the grain would effect its movement.

C shows an SEM image of a single lens & D a Light microscope image the same lens. Figure via Simon Thiele, Kathrin Arzenbacher, Timo Gissibl, Harald Giessen & Alois M. Herkommer

With the curvature at the top, each of the four lenses has a specific line of sight, i.e. clear at the center but blurry at the edges. By 3D printing them in clusters of four, the lenses work together to collect a single picture from their multiple perspectives.

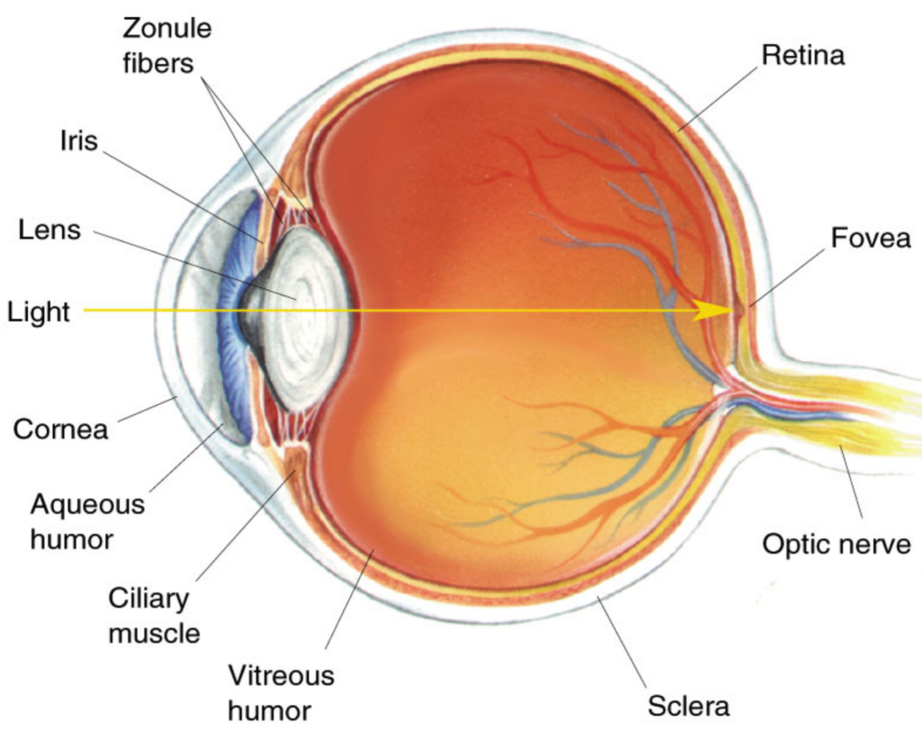

This mimics the way the fovea at the back of the eye collects light, and also how a brain pieces together multiple images from each eye to create one distinct picture.

Diagram of the human eye with a labelled line of sight to the fovea. Image via: The Investment

3D printing makes the impossible possible

One of the main benefits of using 3D printing to make these lenses is that they can be made in one single sweep. It is fast and doesn’t create any material waste. Other technologies trying to instil the same vision in machines work with 3D scanning techniques, e.g. LiDAR imaging for autonomous cars.

Speaking to New Scientist one of the paper’s contributors, Professor Harald Giessen, asserts: “There is no chance you can manufacture imaging systems of this quality by any other means”

Featured image shows an eagle in flight by Oliver Schmidt, os2012 on Flickr

Featured image shows an eagle in flight by Oliver Schmidt, os2012 on Flickr

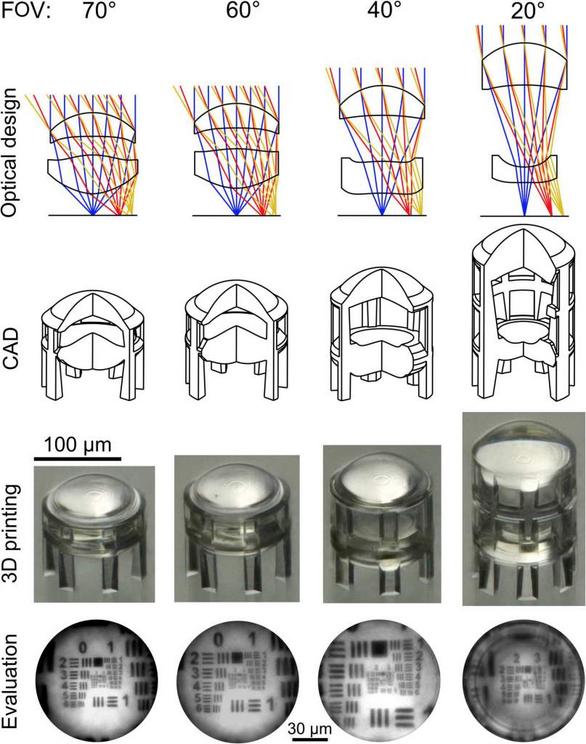

3D printing also means that designs can be quickly reiterated to achieve a desired result. In this study, researchers trialled four different designs to refine the degrees of light entering the lens and assess how it affects the recorded image.

The four different lens designs and their recorded images. Figure via Simon Thiele, Kathrin Arzenbacher, Timo Gissibl, Harald Giessen & Alois M. Herkommer

The research was conducted by a team composed of Simon Thiele, Kathrin Arzenbacher, Timo Gissibl, Harald Giessen, and Alois Herkommer. The full methodology and results are available under an open source license from the Journal of Science Advances, under the title 3D-printed eagle eye: Compound microlens system for foveated imaging.

To stay up to date with the latest 3D printing research and news, sign up to the 3D Printing Industry newsletter here, follow us on Twitter @3Dprintindustry, or like us on Facebook.