Old coal mines could be turned into giant underground farms

Unused coal mines will be re-purposed and used as underground farms under plans laid out by the president of the World Society of Sustainable Energy Technologies.

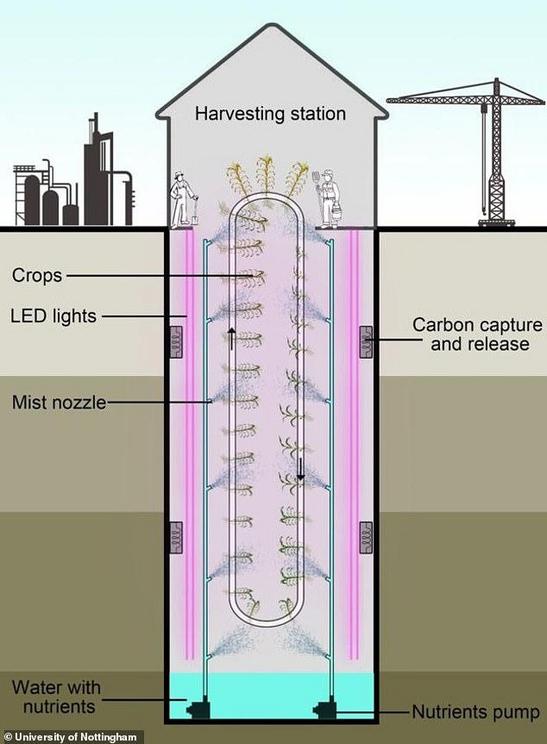

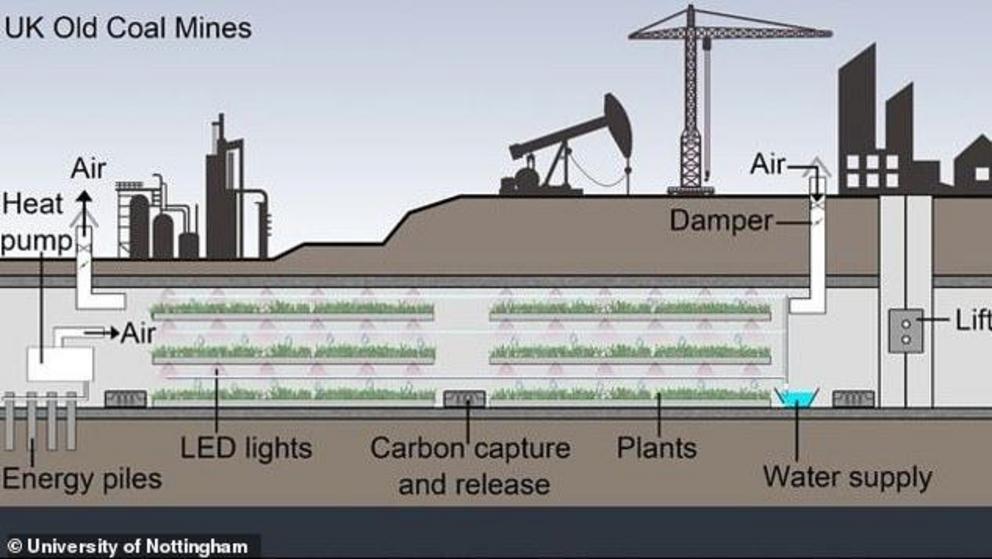

Disused shafts will be fitted with specialist LED lighting designed specifically for certain crops and they will be grown in water-based solutions, opposed to soil, to optimise yields.

The 'deep farms' will drop baskets of plants into the ten foot-wide shafts and they will be hauled back to the surface at harvest time.

Stable temperature of the subterranean farms and absolute protection from pests and disease would allow for up to ten harvests per mine, the researchers claim.

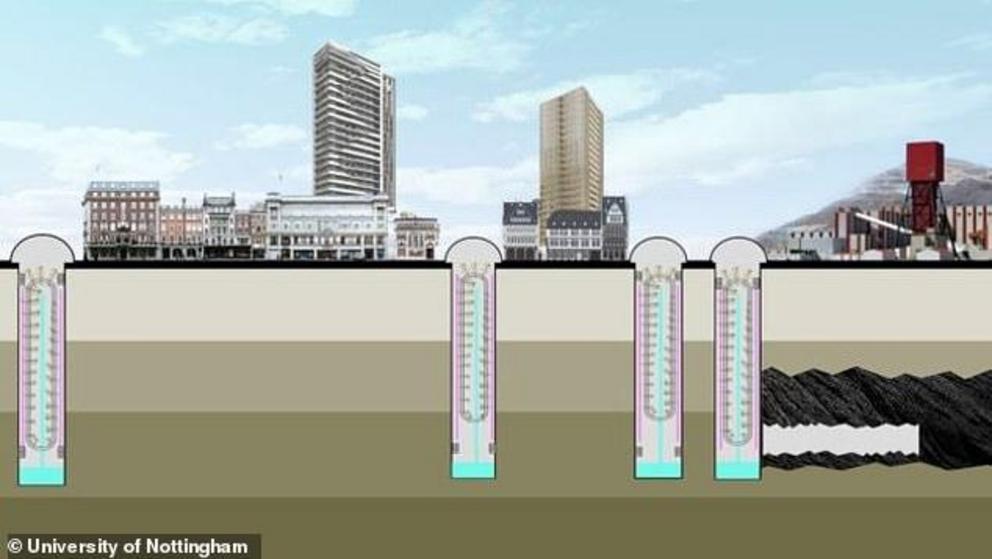

Technology, inspiration and infrastructure for the endeavour came from the advent of 'vertical farms', with Scunthorpe, Lincolnshire, home to the first in the UK.

Deep farms can be operated and harvested entirely by robots and would require no human staff to go underground.

Disused shafts will be fitted with specialist LED lighting tailored for specific crops and plants will be grown in water-based solutions, opposed to soil, to optimise harvests. Deep farms can be operated remotely and would require no human staff to go underground

The initiative also claims that purpose-drilled shafts could be made near densely populated areas to provide extra food and reduce transport distance.

Professor Saffa Riffat, president of the World Society of Sustainable Energy Technologies, based at Nottingham University, claims the low-maintenance project would cost only £30,000 to create and would require the energy equivalent of three houses.

Each relatively undemanding endeavours would, however, would be capable of producing 80 tonnes of crops annually.

At the heart of the operation is a technique known as hydroponics, whereby plants are grown under artificial light with their roots resting in a 'hydroponic solution' made up of water and essential nutrients such as potassium, calcium, nitrogen, nitrate and magnesium, instead of soil.

During the growing process, the water is also periodically drained away ensuring the plants' roots are able to 'breathe in' enough oxygen.

'This could transform the way we farm and the way we feed the world's growing population while helping to tackle the causes of climate change,' he said.

'Some crops are best located underground, leaving the ground surface for human and animal activities.'

'Tunnels and shafts would need less energy with heating, so are very attractive for food production. They're almost perfect.'

Sceptics of the proposal say the unpredictability of using deep tunnels could make the project difficult.

The Coal Authority, which presides over all disused and working mines, is open to novel uses of the wasted shafts but says it could present unique technical, legal and financial challenges.

Reopening the mines, they say, could open Pandora's box of problems including rising water levels, underground gases and tunnel collapses.

A spokeswoman for the Coal Authority said: 'Any schemes involving former coal mines would inevitably throw up many technical, legal and financial challenges that would need to be overcome when creating an accessible and safe working environment.'

Euan Hall, chief executive of the Land Trust, told the BBC that the deep farms were a great idea.

'Deep farms' will drop baskets of the plants into the ten foot-wide shafts and they will be hauled back to the surface at harvest time. They would cost £30,000 and would require the energy of three houses, scientists say

A single mine shaft would be capable of producing 80 tonnes of crops annually, researchers claim. At the heart of the operation is a technique known as hydroponics, whereby plants are grown under artificial light

'There are some obvious challenges, not least that many shafts have been capped or have been built on, but there are lots of coalfields where there is no community around them, where this is clearly something worth looking at,' he said.

Last month, Britain's first 'vertical farm' opened in Scunthorpe, Lincolnshire.

The county is famed for its flat land and farming proficiency but the enclosed warehouse is devoid of any natural light and is manned by four people.

Pink light emanates throughout the warehouse on an industrial estate which is filled with racks of plants stacked 40ft high and tended by a robot that glides about the floor.

The few humans present on this farm look nothing like farmers. Instead of sporting favourite old pullovers or check shirts, they wear overalls, high-vis jackets and hairnets.

In fact, only four human beings work in the vast warehouse.

In order to avoid the plants being contaminated by micro-organisms that can cause diseases such as blight, they have to follow a strict handwashing procedure, after which they must don protective overalls.

They then have to pass through an 'air shower' which blows off any remaining rogue particles.

Technology, inspiration and infrastructure for the endeavour came from the advent of 'vertical farms', with Scunthorpe, Lincolnshire, home to the first in the UK

It's run by a firm called Jones Food Company, and is designed to produce 500 tonnes of plants annually starting with coriander, basil, dill and chives to feed the growing appetite for fresh herbs all year.

Almost the entire procedure is automated. A single robot — called Frank — is responsible for gathering up the trays of plants and taking them around the various parts of the farm, including the seeding and germination areas, and ultimately, the harvesting room.

All this is despite the fact that at no stage do any humans actually touch the plants themselves.

Pure carbon dioxide is pumped into the room, which enables the plants to absorb 50 per cent more than they would in a traditional greenhouse, causing them to grow faster than normal.

All the air that enters passes through medical-grade filters, and the pressure inside the warehouse is kept higher than the air pressure outdoors to stop insects getting in.

Pink light emanates throughout the warehouse on an industrial estate which is filled with racks of plants stacked 40ft high and tended by a robot that glides about the floor. The farm in Scunthorpe boasts no less than 7.6 miles of LED lights, the equivalent of 38 Eiffel Towers

The farm in Scunthorpe boasts no less than 7.6 miles of LED lights, the equivalent of 38 Eiffel Towers laid end-to-end. Their pink glow illuminates a total growing surface area of 5,120 square metres — the size of 26 tennis courts.

The company’s co-founder and chief technology officer, Dr Paul Challinor, who has a doctorate in hydroponics and who did much of the testing of the lights at his own home, explains why his warehouse is lit in that eerie shade of pink.

‘The reason is because the plants grow best under red-and-blue light,’ he says, ‘although we also have white lights so that we can see what we are doing.’

The different-coloured lights have different roles to play during the plants’ life cycles. Red light helps to promote leaf coverage, whereas blue light promotes plant structure and leaf mass.

By 2050 it is estimated around 86 per cent of people in the developed world will be living in cities and the world’s population is projected to have swollen from 7.7 billion today, to nearly ten billion.

Proponents of vertical farms have argued that as the food could be grown in the heart of cities, food miles — the distance it travels from traditional farms to consumers — could be all but eliminated, cutting greenhouse gas emissions and leaving us with fresher, tastier food.

Video can be accessed at source link below.