Why was Roman concrete so durable? Scientists say it could heal itself

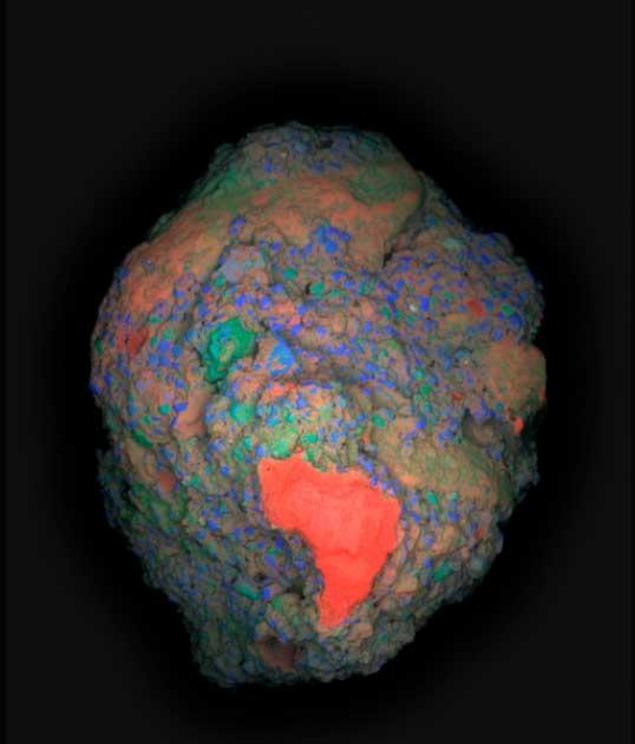

Top image: Right; A large-area elemental map of a 2 cm fragment of ancient Roman concrete showing a calcium-rich lime clast (in red), which is responsible for the unique self-healing properties in this ancient material. Left; The archaeological site of Privernum, Italy where the sample was collected.

Materials scientists have been working with archaeologists and historians for many years, attempting to unlock the fascinating secrets of Roman Empire concrete-making technologies and techniques, which allowed the Romans to construct some of the most enduring monuments the world has ever seen. In a new study published in Science Advances , researchers from the Massachusetts Institute of Technology and Harvard University, assisted by experts from laboratories in Germany and Switzerland, have disclosed what they believe is the key fact that explains why Roman concrete was of such high quality.

The Legacy of Roman Architecture

Among their greatest accomplishments, the ancient Romans perfected the art of building on a grand scale . Their architects and engineers constructed a complex and extensive network of roads, aqueducts, bridges, ports, stadiums and public buildings that have largely survived to the present day.

Roman concrete formulas are a mesmerizing topic from an historical standpoint, but from a practical perspective what the Romans knew could conceivably help improve concrete-making methodologies even today.

Searching for answers, researchers have invested much time and energy studying Roman concrete structures , closely analyzing samples in an attempt to identify their most essential ingredients. The team of scientists responsible for the latest findings includes MIT professor of civil and environmental engineering Admir Masic and former MIT doctoral student Linda Seymour, who were both involved in a landmark 2021 study of the 2,053-year-old Roman tomb of a noblewoman named Caecilia Metella, which has remained largely undamaged despite the immense passage of time.

The interior of Caecilia Metella’s tomb on the Appian Way has stood the test of time because of the secrets of Roman concrete.

The interior of Caecilia Metella’s tomb on the Appian Way has stood the test of time because of the secrets of Roman concrete.

Masic, Seymour and the other scientists who participated in that study found that an incredibly strong mortar made from hydrated lime and volcanic glass was the primary factor that had allowed the tomb to remain intact since its initial construction during the final days of the Roman Republic .

Now, along with a new group of experts, Masic and Seymour have made yet another important discovery about Roman concrete construction techniques that helps explain the amazing lifespans of their structures. And interestingly enough, once again a unique material made from lime has been shown to have made the decisive difference.

How the Romans Manipulated Chemistry to Produce History’s Most Durable Concrete

For a long time, researchers were convinced that a special type of volcanic ash included in Roman concrete was the primary reason for its durability. The type of ash in question was known as pozzolanic ash, as it came from eruptions that had occurred around the city of Pozzuoli on the Bay of Naples. This specific ash was widely used in construction projects across the Roman Empire , being sought after because of its hard and hardy chemical composition.

But this volcanic ash was not entirely responsible for the durability of Roman concrete, the MIT scientists and their colleagues have revealed. During an extensive examination of several samples, the researchers found that ancient concrete-manufacturing methodologies included what they refer to as “key self-healing functionalities.”

What this terminology is referring to are tiny, bright white chunks of mineral known as “lime clasts” that can be found in abundance in Roman concrete.

A magnified piece of Roman concrete consisting of lime, volcanic sand, and rock

A magnified piece of Roman concrete consisting of lime, volcanic sand, and rock

Previously, it had been assumed these chunks of hardened lime were contaminants that played no essential role in the concrete formula. But Admir Masic had always been skeptical of this idea, and set out to prove that it wasn’t true.

“Ever since I first began working with ancient Roman concrete, I’ve always been fascinated by these features,” he explained. “The idea that the presence of these lime clasts was simply attributed to low quality control always bothered me. If the Romans put so much effort into making an outstanding construction material, following all of the detailed recipes that had been optimized over the course of many centuries, why would they put so little effort into ensuring the production of a well-mixed final product? There had to be more to this story.”

And indeed there was. The scientists used high-resolution imaging and chemical mapping techniques pioneered at MIT to examine the lime clasts at a molecular level. When they did so, they found telltale signs showing the clasts had been subjected to high heat, which when applied to limestone produces a substance known as quicklime.

The quicklime was created intentionally as an extra ingredient in the concrete, the scientists found, and was not an unwanted contaminant at all.

“The benefits of hot mixing are twofold,” Masic noted. “First, when the overall concrete is heated to high temperatures, it allows chemistries that are not possible if you only used slaked [cold mixed] lime, producing high-temperature-associated compounds that would not otherwise form. Second, this increased temperature significantly reduces curing and setting times since all the reactions are accelerated, allowing for much faster construction.”

As a result of the hot mixing process, the lime clasts produced were quite brittle, enough so that when anything caused the concrete to start cracking the force would be translated to the lime clasts, which would then begin to crack as well. Incredibly, the crumbling lime clasts would then react with water penetrating the concrete through the cracks, creating a calcium-saturated solution that would both harden to fill all the cracks in the concrete and react with the pozzolanic materials to add extra strength to the blocks.

In other words, the lime clasts would automatically “heal” the concrete whenever the forces of nature threatened to break it apart.

A calcium-rich lime clast (in red), which is responsible for the unique self-healing properties in this ancient material, is clearly visible in the lower region of the large-area elemental map (Calcium: red, Silicon: blue, Aluminum: green) of a 2 cm fragm

A calcium-rich lime clast (in red), which is responsible for the unique self-healing properties in this ancient material, is clearly visible in the lower region of the large-area elemental map (Calcium: red, Silicon: blue, Aluminum: green) of a 2 cm fragm

To test their conclusions about the lime clasts’ self-healing capacities, the researchers produced hot-mix concrete samples using both ancient Roman and modern concrete-making formulas. They then cracked the various samples on purpose and poured water through the cracks to see what would happen.

Just as predicted, after no more than two weeks the cracked blocks made from Roman Empire concrete completely healed and were no longer vulnerable to water penetration. Conversely, the samples made from modern concrete formulas stayed cracked and would have further deteriorated if subjected to continuous water flow.

Could Roman Concrete Be Used Today? Scientists Want to Know

Thrilled by their test results, the scientists are now seeking partners to finance the commercialization of Roman-style concrete, which offers clear advantages to most modern versions.

“It’s exciting to think about how these more durable concrete formulations could expand not only the service life of these materials, but also how it could improve the durability of 3D-printed concrete formulations,” Masic said.

In Admir Masic’s research lab at MIT material scientists are experimenting with new concrete formulas that could possibly reduce the impact of cement production on global climate (cement making currently accounts for approximately eight percent of global greenhouse gas emissions). Masic points out that longer-lasting concrete could help lower this percentage, since cement block structures that lasted as long as Roman aqueducts or public buildings wouldn’t need to be repaired or replaced very frequently.